Over pressure autoclave sterilizer, overpressure retort design and physical principle , water spray retort sterilizer, saturated waterspray autoclave

Sterilizer

professional

professional

Saturated water spray sterilization process with over pressure autoclave

Overpressure retort sterilizer / autoclave sterilization process equipment / disinfector / asepticizer

Full Automatic Water Steam Spray Batch Retort, Batch Autoclave Sterilizer

Computer control sterilization process / save steam energy and time

operation system and process

sterilization operating system and sterilizer process control function

retort sterilizer thermal history

compare list of thermal history water spray / water immersion

save energy sterile equipment

Energy consumption / save steam / save energy / save time

The batch retort sterilizer temperature standard reference point

The calibration of Mercury-In-Glass (MIG) thermometer

- The US Code of Federal Regulations

- The sterilization autoclave must have a mercury-in-glass thermometer with divisions easily readable to 1°F and a temperature range not to exceed 17 °F per inch of graduated scale.

- Thus, to insure accurate autoclave sterilization temperature reading the MIG thermometer must be checked for accuracy once a year against a known accurate standard thermometer upon installation and at least once a year thereafter.

- The date of the test should be placed on the MIG thermometer so that the operator can readily see when the next check for accuracy is to be made. Checks for accuracy should be done at the approximate scheduled autoclave sterilization temperature.

- The date and name of the individual testing thermometers should be logged and filed.

- Resistance thermometer (RTD) devices are generally used as the reference thermometer for programmable controlling systems. In no case will the RTD replace the MIG as the reference thermometer for the sterilization autoclave

- The recording temperature device should have graduations no to exceed 2°F (1℃) within range of 10°F (5.5 ℃) of processing temperature.

The temperature should agree as nearly as possible, with the known accurate mercury-in-glass thermometer

Autoclave basic physics theory, sterile mechanical principle

Physics theory

- Thermodynamic equilibrium: Steam and saturate water phase equilibrium, liquid phase and steam phase balance in the close autoclave chamber system

- The zeroth law of thermodynamics : Thermal equilibrium; multi-material temperature balance system

Autoclave / retort sterilization machine mechanical principle

- Steel thermal transfer conductivity : 54 Kcl/(hr)(m2)(℃)

- Steam to saturate water thermal transfer conductivity : 5,000 ~ 10,000 Kcl/(hr)(m2)(℃)

- Heat exchanger was heat conductivity transfer system, water steam spray retort system was direct thermal transfer system

- Thermal transfer area : Small drop would expand the thermal transfer area to very large into the retort sterilizer

- A few circulation liquid could be doing the thermal translation function

- Close equilibrium cycle system for cooling process, its save for food and pharmacy sterilizing process

- Equipment

- Sterile equipment

- Hot waterspray

- Steam autoclave

- Used Retort

- Sterilisation

- Sterilization

- Foods sterile

- Sterile package

- Sterile pouches

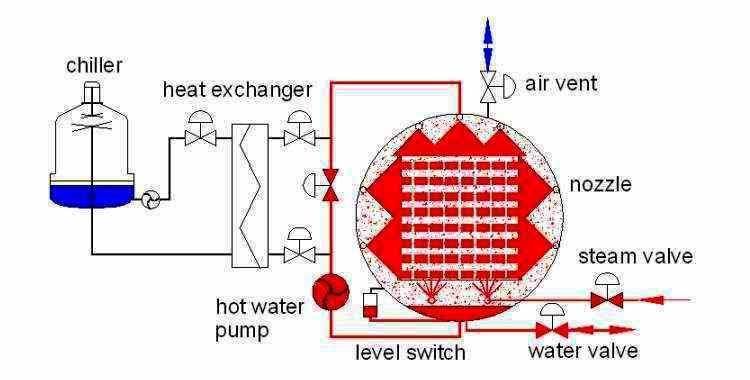

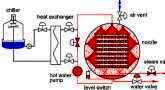

Cross section layout of autoclave sterilizer / retort sterilizer ( sterilize condition)

The autoclave heat exchanger was option equipment; the autoclave heat exchanger is for cooling cycle only, not for heating propose, The autoclave / retort sterilizer heat distribution and heat penetration study testing and recorder system, its follow as US FDA CFR regulations

Sterilization process: Water Steam Spray Batch Retort, Batch Autoclave Sterilizer

Before sterilizing process

- Hot filling sterilizing process: should be pre-heating , the temperature was same as products hot filling temperature, then the product push into the waterspray autoclave chamber

- Glass bottles: hot filling glass bottles need preheating before start sterilizing process, because the temperature differential between glass bottles and room temperature too large , the glass container would crack

- The working medium should be soft water (its same as steam generator supply water)

Prepare sterilization process:

- Maker setting: at initial in the autoclave chamber is dry, when process is done, all circulation water was automatically exhaust out of chamber

- Stand by: maker setting automatically shut down all control system and mechanical system except power

- Products package can't broken, should be good arrangement of bottles or flexible pouches package, its necessary

for good sterilizing process

Starting food sterilization process: ( One Touch start )

- Clean soft water inlet to the sterilization autoclave chamber, its automatically control by level switch

- Automatically start circulation pump, automatically steam inject into retort sterilizer chamber, compress air inlet to autoclave sterilizer for over pressure balance system

- Start heating process, temperature rise up speed could be adjust between 3~15℃/min ( 5~27°F/min)

overpressure autoclave heating process:

- Circulation fluid inject into the autoclave sterilizer from top and site, the injection nozzle spray the circulation liquid to " droplets"

- Millions of droplets be heating immediately in the space of autoclave chamber

- Uniform distribution of temperature, the nozzle's injection force drive the droplets to everywhere in the chamber

Sterilization temperature of autoclave / keeping process :

- Temperature reaches the set point temperature, starting sterilization process

- The average temperature precision keep in ±0.5°C (±1.0°F) during the process

- Sterilizing process approach to constant temperature and constant pressure physical equilibrium circulation

- Saturate water sterilization process never over heating the products, best remain protein and glucose, excellence mouth feeling

- Option equipment: sterilization F value online recorder

Sterilization process finish :

- Time reaches the set time, (F value been sufficient), sterilizing process is finish

- Automatically shut down the steam, and automatically starting the cooling system

- Hot circulation water would be cooling by the heat exchanger, the cold circulation water inject into the over pressure retort sterilizer ( autoclave ) chamber to cooled the product

- Cooling speed could be adjust between 5~15℃/min ( 9~27°F/min)

Autoclave sterilizer cooling process :

- Hot circulation fluid was cooling by heat exchanger, the cold liquid inject into the autoclave sterilizer, the cold liquid with nozzle spray its to " droplets", cold droplets "pull out" the thermal from products, the products should be cooling

- With close circulation system, the asepsis circulation is the best for cooling process, the working medium had been fully sterilizing, its clean and asepsis

- With close cooling system save a lot of cooling water, only need about 3-7% cooling water of full water immersion autoclave sterilizer

Steamwater spray retort / autoclave working process / finish :

- Final cooling temperature is higher then the temperature of environment, average higher 15℃( 27°F), the products temperature would between 30~45℃ ( 85 ~ 115°F), for special propose, you can set the final cooling temperature more higher, but never over 60℃ ( 140 °F), because after cooking were keeping cooking the product, final high cooling temperature would damage your products, its cause over cooking

- Cooling speed too slowly or sterilization time too long or final temperature too high, all will damage your products, its loss a lot of nutrition

- Super cooling : Its option function; products cooling temperature between 20℃ ~ 25℃ ( 70 ~ 80°F), with chiller the products will be cooling to room temperature

Remark :

- This retort / autoclave machine was design for wet sterilizing purpose, the goods container or package should be

water-repellent, usually with close container package material, but it's not

true.

This autoclave machine can do the working without vacuum sealing container, for example : a pot with waterproof cap, its can cooking or boiling the food without vacuum package material. - Sterilize inflation package container : many container can't be vacuum, for example ; soft can with liquid, or sauce or puree or paste, but all can be sterilizing with our overpressure water spray autoclave sterilizer.

- Dry sterilizing method or pasteurization or pasteurizer or pasteurizing column or flash pasteurizer can't be doing with this wet water spray retort sterilizer, the physical process and physical property was different, the germicidal action was different, the storage was different too

- All the autoclave sterilizer function design was follow as the

regulation of:

- USA FDA ( UNITED STATES OF AMERICA, Food and Drug Administration )

- TAIWAN FIRDI (The Food Industry Research and Development Institute) is a non-profit legal entity established in 1965 with financial support from the Canners' Association of Taiwan ,CIECD (Council for International Economic Cooperation and Development) and JCRR (Joint Commission on Rural Reconstruction).

- The autoclave mechanical design (pressure vessel design) follow as :

- ASTM---- American Society for Testing and Materials

- ASME---- American Society of Mechanical Engineers

- JIS------- Japan Industrial Standard

- CNS----- CNS regulation 9788 (Taiwan)

- Warning: Autoclave utility system

- Water supply for autoclave / retort sterilizer

- The source should be clean or soft water, the supply could be from steam boiler water treatment machine, or independent treatment equipment.

- Boiled the city water ( hard ), will separate out the calcium carbonate, the calcium carbonate was a small particle; Its would adhere to the package container surface, its was bad products

- The calcium carbonate will adhere to the shell and pipe inner face too, its would damage the equipment, and looking was dirty

- Usually sterilize machine breakdown was caused by the calcium carbonate

- Cleaning the calcium carbonate was hard working, not so easy

- Electrical power supply for autoclave / retort machine

- Electrical power supply should be stable, the differential of voltage should be under 10%, otherwise the driver motor, PLC, relay, micro computer, etc etc would be breakdown or be burnout.

- All the electric wire connector should be waterproof

- Steam supply to retort / autoclave sterilization machine

- The main pipe of steam should keep the pressure above 6 kg/cm2 (85 psi)

- Pressure air supply to sterilization machine / autoclave / retort

- Must have a service tank to storage the pressure air, always keep the air pressure above 5 kg/cm2 (70 psi)

- If insufficient air supply, the pouches package would broken, the machine would unstable

Chang Yu Machinery Tel:+886-4-8525369 Fax:+886-4-8525189 Email:

retort@ms34.hinet.net

copyrights reserved