Over pressure retort sterilizer, overpressure retort function, hot water spray retort sterilizer, saturated waterspray autoclave, pharma sterilizer

Best choice of autoclave sterilizer / pressure retort sterilization process

For all heat resistant / waterproof package container / best nutrition preservation for protein / glucose

Pressure vessel inspection

ASME "U"-STAMP / AI (ASME Authorized Inspection Agencies) / JIS / CNS9788 / 9802

Computer control Water Spray Batch Sterilizer, Batch Autoclave Sterilizer

Foods sterile process machine

One touch foods disinfect machine / pharma disinfector

sterilization process monitor

Color monitor with human machine interface (H.M.I) monitor

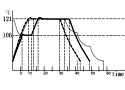

kinds sterilizer heating process

the sterilizing heat process of kinds retort sterilizer / disinfector

Save your energy cost

Save steam / save sterilization water / save sterile time

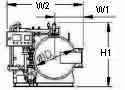

Steam / Water Spray autoclave sterilizer Specification and Characteristic

Retort / Autoclave Function: CY3000 steamwater spray autoclave sterilizer

Mechanical function :

The sterilization machine function of CY3000H saturate hot water spray sterilizer system

- General specifications :

- Pressure function :

- Design pressure: __________________ 7 kg/cm2 (100 psi)

- Inspection pressure: ________________4 kg/cm2 (57 psi)

- Operating pressure: ________________2 kg/cm2 (30 psi) ( over pressure )

- Temperature function :

- Autoclave / retort operate temperature: form ______ 80 ~ 130℃ ( 180 ~ 265 °F)

- Cooling temperature: outdoor temperature plus ___ 15 ℃ ( 27°F)

- Autoclave retort temperature distribution : ._______ ± 0.5 °C ( ± 1.0 °F)

- Heating speed : adjustable .___________________ 3 ~ 10 ℃/min (6 ~ 27 °F/min)

- Cooling speed : adjustable .___________________ 3 ~ 10 ℃/min (6 ~ 27 °F/min)

- MIG thermometer : __________________________ 80 ~ 130 ℃ (175 ~ 265 °F), indicate 0.5 ℃ (1 °F)

- Room temperature : above .___________________ 4 ℃ ( 40 °F)

- Material :

- Shell: stainless SUS 304 (with the origin steel sheet number certificate documents)

- Shell: stainless SUS 316 (with the origin steel sheet number certificate documents)

- Machine frame : SUS 304

- Fasten parts : SUS 304 (bolts, nuts, washer)

- can't be carbon steel : First: the iron corrosion rust would damage the control valve , Second; the corrosion rust would contaminate the surface of goods

- Electrical instrument :

- German : Siemens

- Japan : Shimaden, Fuji, Mitubishi

- Taiwan : Shihlin Electric & Engineering Corp, Taian Electric, Delta Electronics, TECO Electric & Machinery

- Pipe system standard :

- ANSI #150 (150LBS)

- DIN 10 kg/cm2

- JIS. 10 kg/cm2

- Option equipment :

- Super high temperature sterilization : sterilization temperature above 130 ℃ (265 °F)

- Under cooling temperature : 20 ~ 25 ℃ (70 ~ 80 °F)

- Asepsis sterilization process : ( applied to Pharmacy and medical and drug commercial sterilization process)

- Compresses air asepsis micro filter

- steam asepsis micro filter

- Close circulation asepsis sterilization process

- Sterilization F value recorder , (approved style and general style)

- Automatically loading unloading equipment

- Appearance :

- Head was grinder polish #250 mesh

- Chamber inner face site was grinder polished #250 mesh

- Stainless pipe was grinder polish #250 mesh

- Operation control box was sand polish plate

- Insulation was bundle with stainless sheet

- Equipment

- Sterile equipment

- Hot waterspray

- Steam autoclave

- Used Retort

- Sterilisation

- Sterilization

- Foods sterile

- Sterile package

- Sterile pouches

All in one : For all heat resistant and waterproof package material

Full Function autoclave sterilizer :

CY-3000H autoclave sterilization function characteristic / retort sterilization function

- Large operate range

- Operating temperature range : form 70 ~ 130℃ ( 160 ~ 265°F), (option : over 130℃ / 265°F)

- Operating pressure range (over pressure): max 4 kg/cm2 (57psi)

- Applied to all heat resistant and waterproof package material

- Applied to nitrogen inflation sterilization process

- Applied to open container with waterproof

- Applied to static autoclave sterilization and rotary autoclave sterilizer

- For all heat resistant and waterproof package material

- Flexible pouch serial: flexible retort pouch, retortable pouch bag, retort pouch,

nylon pouch, retort food pouch, soft can, stand up retort pouch,

laminated film bag, laminated retort pouch, high temperature cooking bag, pouch food

sterilization, vacuum cooking bag, vacuum retort pouch, aluminum foil bag, aluminum retort pouch, aluminum

vacuum pouch

- Mental can serial: tin can . tin canned, aluminum can, canned food, can food, square can, poptop can, 2 piece can, 3 piece can, canned food sterilization

- Glass container serial : Glass bottle , glass jar, glass container sterilization

- Plastic container serial : PP bottles, PP can, PP tray, PP cup, PP container, HDPE bottles, HDPE can, HDPE tray, HDPE cup,

HDPE container, Nylon bottle, nylon cup, nylon tray

- Medical devices serial (need waterproof package) : Medical devices sterilization, Medical tool sterilization, Laboratory tools sterilizing

- Pharmacy and drug serial : Amber Glass Bottle, amber glass bottle leak testing , Injection drop bag, Injection drop bottles, Oral dose sterilization,

Contact lens sterilizing, Biotechnology production sterilization

- Nitrogen inflation sterilization process

- Retort pouch nitrogen inflation sterilization process

- Aluminum foil nitrogen inflation sterilization process

- High temperature cooking bag nitrogen inflation sterilization process

- Transparent pouch nitrogen inflation sterilization process

- Open container with waterproof sterilization process

- A pot with waterproof cap

- Leafage with waterproof package

- Egg cooking

- Crustacea sea food sterilization

CY-3000H autoclave sterilization function characteristic / retort sterilization function

- Large operate range

- Operating temperature range : form 70 ~ 130℃ ( 160 ~ 265°F), (option : over 130℃ / 265°F)

- Operating pressure range (over pressure): max 4 kg/cm2 (57psi)

- Applied to all heat resistant and waterproof package material

- Applied to nitrogen inflation sterilization process

- Applied to open container with waterproof

- Applied to static autoclave sterilization and rotary autoclave sterilizer

- For all heat resistant and waterproof package material

- Flexible pouch serial: flexible retort pouch, retortable pouch bag, retort pouch, nylon pouch, retort food pouch, soft can, stand up retort pouch, laminated film bag, laminated retort pouch, high temperature cooking bag, pouch food sterilization, vacuum cooking bag, vacuum retort pouch, aluminum foil bag, aluminum retort pouch, aluminum vacuum pouch

- Mental can serial: tin can . tin canned, aluminum can, canned food, can food, square can, poptop can, 2 piece can, 3 piece can, canned food sterilization

- Glass container serial : Glass bottle , glass jar, glass container sterilization

- Plastic container serial : PP bottles, PP can, PP tray, PP cup, PP container, HDPE bottles, HDPE can, HDPE tray, HDPE cup, HDPE container, Nylon bottle, nylon cup, nylon tray

- Medical devices serial (need waterproof package) : Medical devices sterilization, Medical tool sterilization, Laboratory tools sterilizing

- Pharmacy and drug serial : Amber Glass Bottle, amber glass bottle leak testing , Injection drop bag, Injection drop bottles, Oral dose sterilization,

Contact lens sterilizing, Biotechnology production sterilization

- Nitrogen inflation sterilization process

- Retort pouch nitrogen inflation sterilization process

- Aluminum foil nitrogen inflation sterilization process

- High temperature cooking bag nitrogen inflation sterilization process

- Transparent pouch nitrogen inflation sterilization process

- Open container with waterproof sterilization process

- A pot with waterproof cap

- Leafage with waterproof package

- Egg cooking

- Crustacea sea food sterilization

Protein Glucose protector: best nutrition preservation

Nutrition preservation :

CY 3000H with saturate water sterilization process that's never over heating the foods

- Nutrition destruction :

- Protein destruction: The nutrition of protein was heat sensitivity material, the protein was sensitive to temperature and thermal value, the temperature reached to 72 ℃ ( 162 °F ), the protein would change its property, or over cooking (too many thermal value or cooking time too long), its would change too.

- Glucose destruction: The nutrition of glucose was heat sensitivity material same as the protein, if over cooking or over heating the glucose would carbonization,

and lost its nutrition.

- Best nutrition preservation : never over heating, high precision sterilization F value control

- Least over cooking : Into the autoclave sterilization chamber the saturated small water drops "impact" to everywhere of the chamber, the temperature distribution and hest penetration was homogenized, the temperature of cold point and hot point was closely, its accurate control the sterilization F value, the products was least over cooking.

- Never over heating :Use saturated water as the thermal medium, at the phase equilibrium condition of liquid phase and steam phase of water, the saturated water was very sensitivity to the thermodynamic equilibrium phase balance, at constant temperature and constant pressure, the saturated water was a thermal sensitivity particle, the phase change was immediately between liquid phase and vapor phase, Its keep the temperature stable, the sterilization products was never over heating.

- The profit of saturated water sterilization process (steamwater spray autoclave sterilization)

- Least protein destruction

- Least glucose destruction

- Best nutrition survivability

- Best mouth feeling

Retort sterilization machine: operating and layout

Autoclave sterilization machine / trolly / basket / retort room

Save Energy 45% :

High energy efficient steamwater spray autoclave sterilizer

Energy compare basic :

Hot water immersion sterilization (double tank retort) and steam sterilization retort

- Save energy :

CY3000 high pressure high temperature autoclave sterilization was specially good at save energy

- Save steam consumption energy _____18%

- Save soft water consumption over ____ 89%

- Save power ______________________44%

- Save the money invested for steam generator and steam supply

equipment (don't need condensed water recover system)

- Save the money invested for soft water treatment and wastewater treatment

- Save equipment maintenance cost

- Create a quite and comfortable operating environment; to fit in with GMP HACCP regulation

- How to do it

- Save water consumption over 89% : CY3000H water spray autoclave only need 5 ~ 8 % cooling water of the autoclave chamber volume

- Traditional sterilizer cooling process wasted a lot of cooling water

- Steam sterilize autoclave cooling process: city

water pumped into the autoclave chamber to cooling the high

temperature product, at the same time , exhausted warm

water, keeping the inlet and exhaust action , till the products be cooling to the set temperature,

the water consumption volume near 3 ~ 4 times of the steam

autoclave chamber volume.

- Full hot water immersion autoclave sterilization cooling process :

city water pumped into the autoclave chamber to cooling the

high temperature product, same cooling process was batch

cooling , some one was continuous cooling process, but all

need cold city water 3 ~ 4 times of the immersion

autoclave chamber volume.

- Vertical autoclave sterilization cooling process : its same as the water immersion autoclave sterilizer cooling process,

its need cold city water 3 ~ 4 times of the vertical autoclave chamber volume.

- Negative factors of city water cooling process:

- Bacterial Contamination again: package material was

heating in high temperature and a long time (121℃ / 15~50mins), the seal and package material should be weak, when pumped into the cold city water ( 25℃ )

the bacterial in the city water " maybe" contaminated the products again.

- Waste a lot of city water, then pay money to treatment the wastewater.

- Waste the invested of water supply and water treatment

equipment

- Asepsis cooling process : Best solution of sterilization cooling process

- Asepsis cooling process: The circulation water had been fully sterilized, change the flow direction , Its pass through the after cooler

( cooling water heat exchanger), then inject into the autoclave sterilization chamber to cooling the products,

its clean and asepsis, no more bacterial contamination again,

the sterilization process was very safe.

- Cooling water consumption was zero : sterilization cooling process

- Close cooling system, the circulation water pass through after cooler should be cooling, the cold water circulated as the sterilization circulation.

- The after cooler was cooling by the chiller (cooling tower ), the thermal was exhaust to the

atmosphere

- High efficiency thermal translate function, steam 100% use up

- Change liquid water to drops by spray nozzle, we can got a

huge thermal exchange area.

-

100 times thermal conductivity efficiency; steam condensed to

saturate water the thermal transfer conductivity was 5,000 ~

10,000 Kcl/(hr)(m2)(℃); carbon steel thermal transfer

conductivity : 54 Kcl/(hr)(m2)(℃) ,

5000/54=~100 times, its means the thermal transfer efficiency of

directly thermal transfer of water and steam, should be 100

times better then the steel and steam thermal transfer

efficiency.

- Water drops fully absorbed the thermal value of steam, the

steam thermal 100% to use, its the best energy efficiency.

- Without any type of heating heat exchanger, save the cost of

sterilize autoclave equipment

- Don't need hot water recover equipment and recover pipe

system, save the money invested of equipment and save

maintenance cost

- Don't need exhaust steam out of autoclave chamber, for the steam autoclave sterilization, during sterilization process, 30% steam should be exhaust for the temperature distribution

- Exhaust steam should be negative factors as:

- Loss a lot of steam energy

- Room temperature should be high ( usually with pipe exhaust to outdoor )

- Noise from high pressure steam exhaust out

- Vapor in the atmosphere condensed into dew, Its should increase the relative humidity, the room environment would be wet

- Solution : with saturate water spray sterilization process

- Steam was inject into autoclave chamber, direct heating the circulation water, the steam thermal value

100% use up, energy loss is 0%, save a lot of energy

- No more noise pollution form high pressure steam exhausting noise

- No more condensed drops, room humidity was

comfortable

- Ideal sterilization process: Fully isolation circulation process: During the sterilization process cycle, the thermal medium of water was restricted in a close system,

Its was isolated system, before the products was pull out of the autoclave

sterilization chamber, the bacterial don't have any change to contact with the products,

Our water spray autoclave sterilization is a Ideal sterilization process

Hot water immersion sterilization (double tank retort) and steam sterilization retort

CY3000 high pressure high temperature autoclave sterilization was specially good at save energy

- Save steam consumption energy _____18%

- Save soft water consumption over ____ 89%

- Save power ______________________44%

- Save the money invested for steam generator and steam supply equipment (don't need condensed water recover system)

- Save the money invested for soft water treatment and wastewater treatment

- Save equipment maintenance cost

- Create a quite and comfortable operating environment; to fit in with GMP HACCP regulation

- Save water consumption over 89% : CY3000H water spray autoclave only need 5 ~ 8 % cooling water of the autoclave chamber volume

- Traditional sterilizer cooling process wasted a lot of cooling water

- Steam sterilize autoclave cooling process: city water pumped into the autoclave chamber to cooling the high temperature product, at the same time , exhausted warm water, keeping the inlet and exhaust action , till the products be cooling to the set temperature, the water consumption volume near 3 ~ 4 times of the steam autoclave chamber volume.

- Full hot water immersion autoclave sterilization cooling process : city water pumped into the autoclave chamber to cooling the high temperature product, same cooling process was batch cooling , some one was continuous cooling process, but all need cold city water 3 ~ 4 times of the immersion autoclave chamber volume.

- Vertical autoclave sterilization cooling process : its same as the water immersion autoclave sterilizer cooling process, its need cold city water 3 ~ 4 times of the vertical autoclave chamber volume.

- Negative factors of city water cooling process:

- Bacterial Contamination again: package material was heating in high temperature and a long time (121℃ / 15~50mins), the seal and package material should be weak, when pumped into the cold city water ( 25℃ ) the bacterial in the city water " maybe" contaminated the products again.

- Waste a lot of city water, then pay money to treatment the wastewater.

- Waste the invested of water supply and water treatment equipment

- Asepsis cooling process : Best solution of sterilization cooling process

- Asepsis cooling process: The circulation water had been fully sterilized, change the flow direction , Its pass through the after cooler ( cooling water heat exchanger), then inject into the autoclave sterilization chamber to cooling the products, its clean and asepsis, no more bacterial contamination again, the sterilization process was very safe.

- Cooling water consumption was zero : sterilization cooling process

- Close cooling system, the circulation water pass through after cooler should be cooling, the cold water circulated as the sterilization circulation.

- The after cooler was cooling by the chiller (cooling tower ), the thermal was exhaust to the

atmosphere

- High efficiency thermal translate function, steam 100% use up

- Change liquid water to drops by spray nozzle, we can got a huge thermal exchange area.

- 100 times thermal conductivity efficiency; steam condensed to saturate water the thermal transfer conductivity was 5,000 ~ 10,000 Kcl/(hr)(m2)(℃); carbon steel thermal transfer conductivity : 54 Kcl/(hr)(m2)(℃) , 5000/54=~100 times, its means the thermal transfer efficiency of directly thermal transfer of water and steam, should be 100 times better then the steel and steam thermal transfer efficiency.

- Water drops fully absorbed the thermal value of steam, the steam thermal 100% to use, its the best energy efficiency.

- Without any type of heating heat exchanger, save the cost of sterilize autoclave equipment

- Don't need hot water recover equipment and recover pipe

system, save the money invested of equipment and save

maintenance cost

- Don't need exhaust steam out of autoclave chamber, for the steam autoclave sterilization, during sterilization process, 30% steam should be exhaust for the temperature distribution

- Exhaust steam should be negative factors as:

- Loss a lot of steam energy

- Room temperature should be high ( usually with pipe exhaust to outdoor )

- Noise from high pressure steam exhaust out

- Vapor in the atmosphere condensed into dew, Its should increase the relative humidity, the room environment would be wet

- Solution : with saturate water spray sterilization process

- Steam was inject into autoclave chamber, direct heating the circulation water, the steam thermal value 100% use up, energy loss is 0%, save a lot of energy

- No more noise pollution form high pressure steam exhausting noise

- No more condensed drops, room humidity was

comfortable

- Ideal sterilization process: Fully isolation circulation process: During the sterilization process cycle, the thermal medium of water was restricted in a close system,

Its was isolated system, before the products was pull out of the autoclave

sterilization chamber, the bacterial don't have any change to contact with the products,

Our water spray autoclave sterilization is a Ideal sterilization process

Chang Yu Machinery Tel:+886-4-8525369 Fax:+886-4-8525189 Email:

retort@ms34.hinet.net

copyrights reserved